- Aramco's CO2 EOR demonstration project at 'Uthmaniyah receives the Asia Corporate Excellence and Sustainability (ACES) award in the 'Green Initiative Award' category

Aramco's carbon dioxide enhanced oil recovery (CO2 EOR) demonstration project at 'Uthmaniyah has received the Asia Corporate Excellence and Sustainability (ACES) Award in the “Green Initiative Award” category.

The ACES Award is an international respected venue that recognizes sustainability efforts cross-industry and across Asia. This is the first time Aramco has been recognized by this award for the CO2 EOR demonstration project's sustainability efforts. The project has now received a total of eight international awards during the last four years, exemplifying the company's superb efforts in sustainability.

Carbon capture utilization and storage (CCUS)

Capturing and storing CO2 underground has the potential to reduce global emissions significantly. CCUS is the process of capturing waste CO2 from large sources, such as power and gas plants, and depositing it underground for storage so it will not enter the atmosphere.

“We are committed to reducing greenhouse gas emissions by focusing our research, development, and funding on high impact technologies that reduce cost and create significant environmental advantages,” Saudi Aramco president and CEO Amin Nasser said during an Oil and Gas Climate Initiative (OGCI) event. OGCI is a partnership of 13 national and international oil companies that strives to reduce greenhouse gas emissions from the industry.

First CCUS project

Aramco launched the Kingdom's first CCUS and CO2 EOR project at 'Uthmaniyah. This project strives to demonstrate the enhancement of oil recovery while supporting the company's sustainability efforts, reducing the carbon footprint through proper capture and utilization of CO2. It is the first of its kind in the Middle East in terms of scale and operation, and one of the largest in the world.

CO2 injection started in July 2015. The project involves capturing a large amount of CO2 per day that would have been otherwise emitted into the atmosphere, compressing the CO2, and piping it across 85 km, and injecting it into a watered out zone of the 'Uthmaniyah field — part of the giant Ghawar field.

“Reducing greenhouse gas emission has been a top priority for our Upstream operations for several years. This includes near zero flaring and CO2 capture and sequestration in our giant oil fields,” said Nasir K. Al-Naimi, acting business line head of Upstream. The project has been an epitome of multidisciplinary and multidepartmental teamwork. It was started with in-house research, followed by the capture facilities' design at the Hawiyah NGL plant, pilot design, drilling of injection, production, and observation wells, tie-in with the gas-oil separation plant, injection of CO2, and a comprehensive monitoring and surveillance program to evaluate the project.

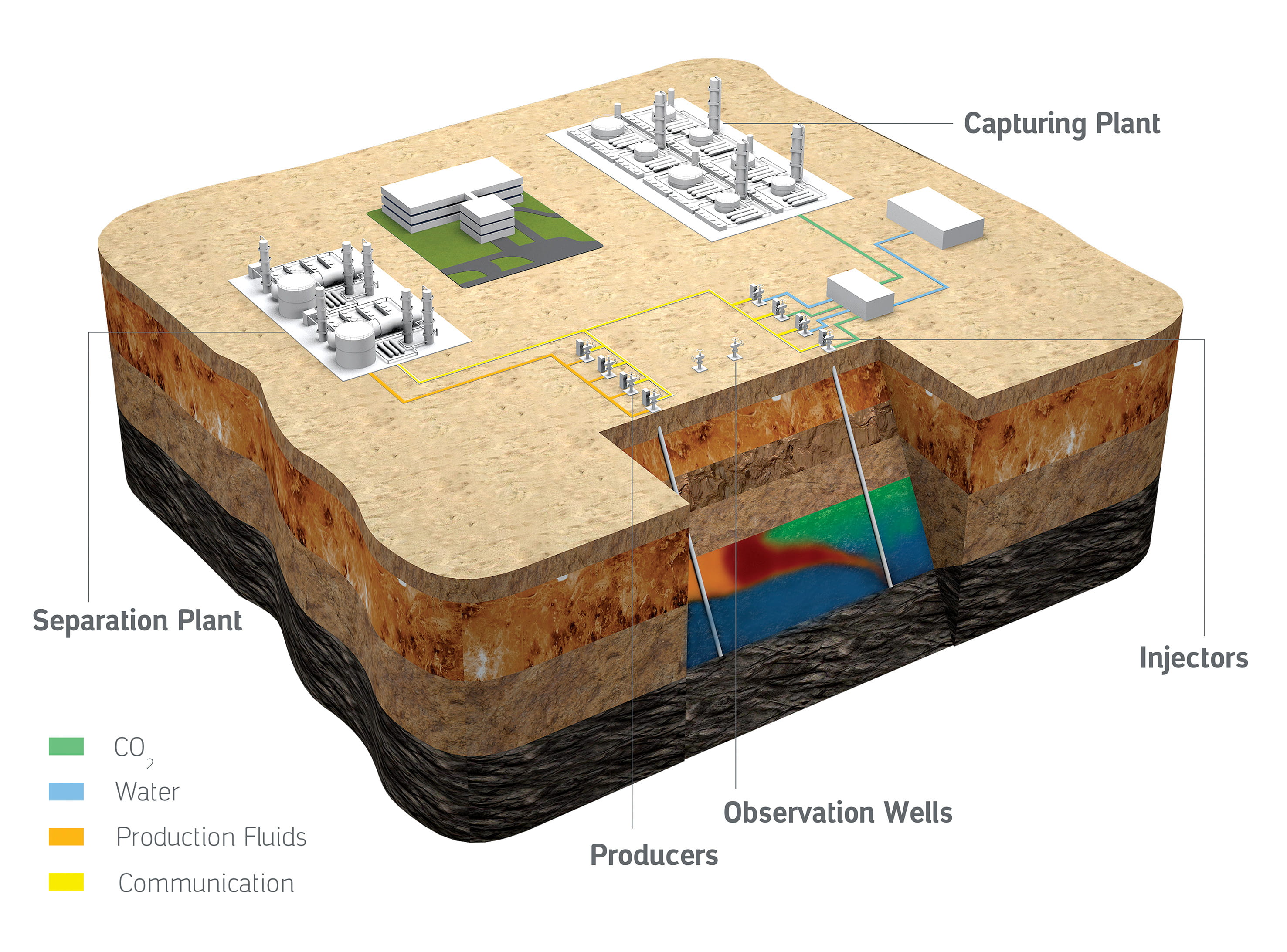

“The primary objectives of the project are to permanently sequester a portion of the injected CO2, and enhance oil recovery beyond waterflooding — a win-win technology solution,” said AbdulHameed A. Al- Rushaid, vice president of Petroleum Engineering & Development. The demonstration project is uniquely designed as an intelligent field project. The entire infrastructure — CO2 capture plant, pipelines, injection manifold; injection, production, and observation wells; wellheads, fluid handling facility, etc. — is fully instrumented to provide real-time data for monitoring and surveillance purposes.

A 3-D model of the CO2 capture plant, injection, production, and processing facilities.

State-of-the-art communications

The project's state-of-the-art communication system allows reservoir engineers to capture and leverage sensor-based data across the whole spectrum to monitor and control the project's performance in real time as well as improve efficiency, sustainability, quality, and safety.

That integrated approach has paid off substantially. Since the initial injection of CO2 in 2015, the production rates have more than tripled and about 60% of the injected CO2 has been permanently sequestered.

The project is an excellent example of Aramco providing, and actually implementing, innovative solutions to address the issue of global climate change. During the past four years, the project has been recognized with eight prestigious international awards.

“The demonstration pilot is part of Aramco's corporate carbon management strategy and road map. It demonstrates the company's pivotal efforts to proactively address global environmental challenges and reduce its carbon footprint. I am proud of the great teamwork by the project team from across the entire company,” said Ashraf M. Al-Tahini, manager of EXPEC Advanced Research Center (EXPEC ARC), the department that spearheaded the project. It involves many of the firsts in terms of technology deployment, some for the first time in the Kingdom, some for the first time in the Middle East, and some for the first time in the world.

Reducing the carbon footprint

The removal and reduction of CO2 emissions is part of a new initiative by EXPEC ARC on sustainability. It focuses on reducing the carbon footprint and intensity of Upstream's operations. The primary driver here is to balance profitability with sustainability.

The program strives to capture the impact of current technologies, identify new opportunities, develop, and deploy new solutions. It adopts the circular carbon economy framework and covers its “4R” pillars of reduce, reuse, recycle, and remove. Depicting the 4Rs on Upstream operations, four major areas have been identified as operational challenges, but at the same time, seen as sustainability opportunities. These areas are carbon sequestration, water management, operational lost time, and reducing material consumption.